CO2 in construction reduced by more than half.

The concrete produced by 3D printing is particularly environmentally friendly. Replacing conventionally processed concrete in the fabrication of a reinforced concrete ceiling, at the points where it is structurally feasible, saves around half of the normal CO2 emissions. It is a greater challenge, however, to use integrated printed concrete elements for the steel reinforcement of floor slabs, as a larger number of manual operations are required in fabrication. That increases the costs. However, TU Graz can also assist here: By using a more sophisticated process, a thin steel cable can be drawn through the printed concrete strands, thereby integrating the reinforcement directly within the printing process.

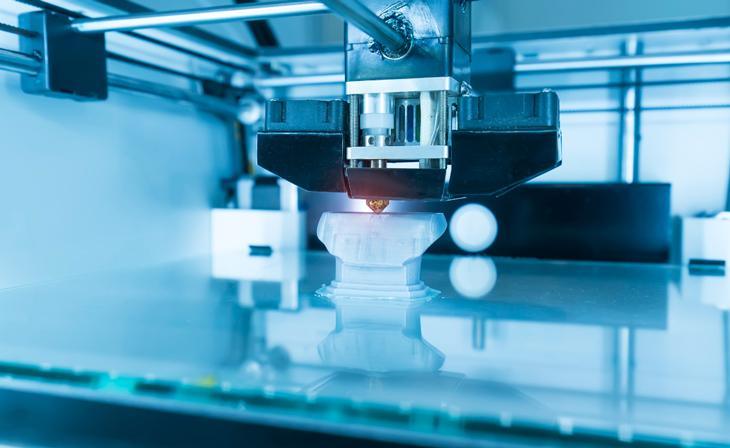

Printed concrete in practice

The first practical experience has already been demonstrated with a studio roof in Lower Austria, followed by the ceiling for an underground car park exit on a housing estate in Bavaria. The construction contractor was responsible for the production of the printed concrete parts, supported and assisted by the team from TU Graz in planning, design and project execution. The concrete elements from 3D printing are, however, sensitive, and TU Graz is currently also developing procedures for safe delivery and storage at the construction site.