Collaborative Research Center "FLAIR

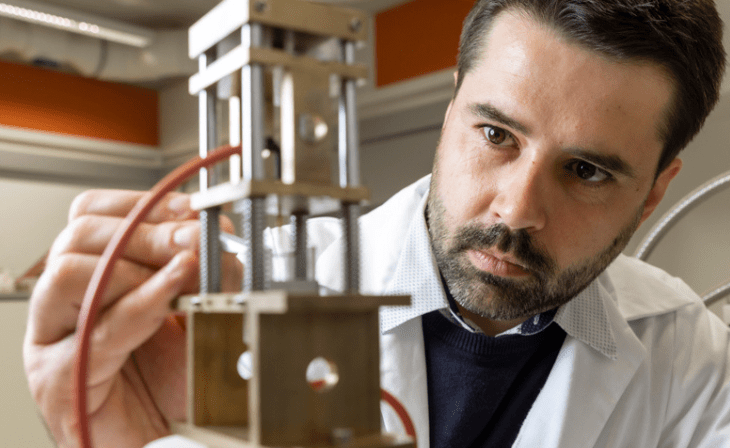

Electroceramics are at the heart of many electronic components. A cell phone, for example, contains 500 capacitors consisting of several layers of ceramic and metal. “In ceramics, we can very well and specifically set properties that the material must have for the particular application,” explains TU Graz materials scientist Jurij Koruza, from the Institute of Chemical Technology for Materials at Technical University Graz. “And they can also be used at high temperatures and other harsh conditions.”

"The heart is the material"

In Graz, the focus will be on the company’s own special field, dielectrics and piezoceramics. For this purpose, ceramic samples are produced by means of solid-state synthesis and doped with different elements in order to specifically change the Fermi level and the defect states. The material is then painted and shaped into the desired form using various processes, such as pressing or 3D printing. After thermal treatment at over 1,000 degrees Celsius, the electroceramics are then given the desired crystal structure, microstructure and defect concentration, which together determine the electrical properties.

Lead-free materials

In addition to the new collaborative research center, the research team is committed to the topic of environmentally compatible materials in electronics. Many electroceramic materials and components today contain lead – a toxic heavy metal. But it is also a heavy metal that is very inexpensive and can be used universally. When used, lead in ceramics is not dangerous to users or the environment because of its stability. The problem, however, is final disposal: Many of our electronic components are not properly disposed of or recycled. Instead, they often end up in unsecured landfills, where they decompose over time, releasing the lead. That’s why researchers are scrambling to find a viable substitute for lead. In a recent paper in Nature Communications, “Tailoring high-energy storage NaNbO3-based materials from antiferroelectric to relaxor states,” Jurij Koruza and his team present just such a material. So there are promising material compositions, the researcher says. But: “Lead is universally applicable. The substitute materials that are being developed are not – they have to be specifically designed for the particular application. So, of course, production is much more costly because companies suddenly have to deal with many materials instead of one.”

Heart

But the researchers are still at it. Because: “In many new applications, it’s not the technology that’s at the heart, but the material. Because the material is responsible for the function – as in solar cells, fuel cells or batteries.”