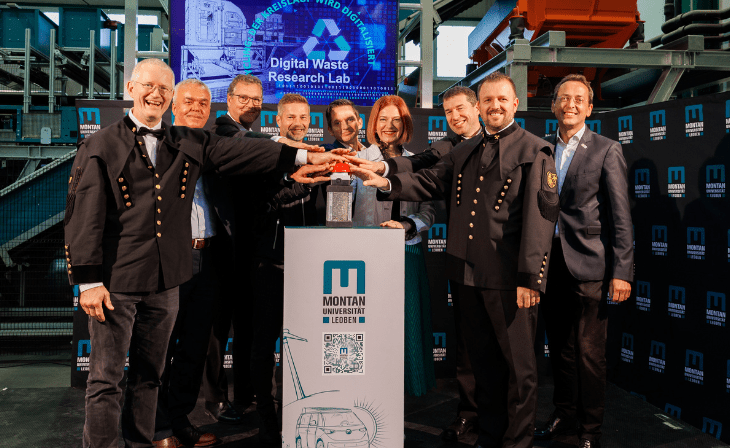

With the recently opened Digital Waste Research Lab (DWRL), Montanuniversität Leoben is putting a new, unique research infrastructure into operation. Green Tech Valley is not only one of the “birth partners” of this new lighthouse, but is also on board with many technology companies such as Siemens, Andritz, Borealis, Komptech, Redwave and Saubermacher.

The recycling-orientated circular economy is an important measure for a climate-neutral future. With the Digital Waste Research Lab (DWRL), Montanuniversität Leoben – Chair of Waste Utilisation Technology and Waste Management – is putting a new, unique research infrastructure into operation. This infrastructure represents an important fundamental and experimental milestone for future-orientated cooperative research. The focus of the research is on particle-, sensor- and data-based waste and recycling technology. Another specialist focus is the digitalisation of waste treatment processes.

“In Styria, we already have a recycling rate of 71 per cent, which puts us among the absolute leaders internationally. Investments in research and demonstration facilities with the highest quality technical solutions, such as the Digital Waste Research Lab, are a guarantee for the further development of resource management in Styria and a significant contribution to climate and environmental protection,” affirmed Provincial Councillor Simone Schmiedtbauer at the opening ceremony on 24 October 2023.

At the opening ceremony, Vice-Rector for Research Prof. Dr Helmut Antrekowitsch emphasised: “With the new research facility, we are building up new technological expertise and strengthening industry-related research. This will enable us to strengthen strategic partnerships with Austrian industry.” Key cooperation partners include technology companies such as Siemens, Andritz, Borealis, Komptech, Redwave and Saubermacher. Experimental research along the cycle and the value chain is the goal.

“We are breaking completely new ground in the training of our students. Students at Montanuniversität Leoben will learn and practise innovative digital methods in the new research facility. True to the university motto: “Where research becomes the future”, our future engineers in the fields of environment, recycling and circular economy will research and learn directly in the plant.

This will position Montanuniversität Leoben even more strongly and effectively as Austria’s resource and recycling university,” Antrekowitsch continues.

New research infrastructure

The new university research infrastructure enables co-operative research in the field of digital waste analysis, waste process engineering and computer-aided waste technology. It has a modular structure and basically consists of process engineering units, various sensors, a sorting unit and a digital data management platform.

“The new research facility is a technical and digital tool for engineers. It allows us to research completely new fundamentals such as digital, sensor-based waste analysis and sorting technologies. Our cooperation partners from industry also have questions that can only be investigated in a research facility like this,” explains Laboratory Head Assistant Professor Dr Renato Sarc.

Chair Professor Dr Roland Pomberger explains: “The great opportunity is when technology companies along the entire circular economy chain and the University of Leoben jointly develop new technologies as well as circular and digital solutions in the new research facility. Digitalisation needs hardware and the new facility is an important component of the infrastructure network. Projects and partnerships will certainly benefit greatly from this. Long-term cooperation between business and science is the key to success.”

Many years of expertise in the field of research

Large-scale process engineering tests are planned for fall 2023 and spring 2024. These will take place as part of the FFG COMET – Competence Centers for Excellent Technologies – project “ReWaste F” funded by BMK, BMAW and the Province of Styria.

Under the name “ReWaste Prototype”, trials are planned in which various processing machines from industrial partners Andritz, Siemens, Redwave, Komptech, IFE and EVK will be used. The aim is to set up and test a “smart waste factory” in which connected machines are controlled by a shared digital database and dynamically modified during operation. The aim is to achieve even better sorting and recycling results that are adapted to the quality of the material.

“Newly recovered fractions and the recyclates produced must meet the quality requirements of today’s products and even more so those of tomorrow so that the cycle can be closed sustainably,” emphasize Sarc and Pomberger.

This large-scale trial also focuses on the integration and interconnection of machines from different manufacturers, using the standard Module Type Package (MTP). The data obtained will provide an important basis for intelligent controls and will also be used as training data for machine learning algorithms and other digitalization topics.

Statements

“With our tailor-made products and solutions in the areas of circular economy, recycling and digitalization, we support customers and industrial partners worldwide in achieving their sustainability goals. Our central focus is on international research and development at the highest level and driving innovation. With the ReWaste F project and the opening of the Digital Waste Research Lab, the Montanuniversität Leoben has achieved a milestone and we are proud to be one of the cooperation partners, especially since the Lab and our ANDRITZ Recycling Technology Center are at the same location. This, in combination with Metris – ANDRITZ Digital Solutions – offers a unique research environment characterized by synergies and partnership,” explains Dipl.-Ing. Alexander Wassermann, Senior Vice President and Head of the Paper, Fiber, and Recycling Division at ANDRITZ AG.

“In the chemical industry, we live high digitalization standards. We see the added value generated with the ambition to transfer this to the circular economy,” adds Dr. Harald Herbst, Head of Competence Center Digital Innovation, Borealis Polyolefine GmbH.

“Digital solutions are a key enabler for the transformation towards a genuine circular economy. Saubermacher has been investing heavily for several years now and, as a leader in waste intelligence, relies heavily on these technologies at all stages of the value chain. For example, we see platforms as the best tool for making optimization potential in waste and resource management transparent and making it measurable,” explains Dr. Andreas Opelt, COO of Saubermacher.

“With tailor-made software, AI applications and automation hardware, we are helping to optimize recycling processes. Together with research partners such as the University of Leoben and companies from the recycling industry, we are developing innovative solutions with the aim of making them global standards in the future. This enables us to provide our customers and partners with the best possible support for their digital and green transformation,” confirms Dipl.-Ing. Herbert Tanner, head of the Siemens branches in Graz and Klagenfurt and head of the industrial software development team at Siemens Austria.

Strengthening the innovation density in Green Tech Valley

“With the newly opened Digital Waste Research Lab and the corporate collaborations, Green Tech Valley now offers pioneering research infrastructures for the circular economy throughout Europe. This will massively strengthen the profile of the Montanuniversität as a hotspot for circular innovations,” emphasizes Bernhard Puttinger, MBA Managing Director Green Tech Valley Cluster GmbH.