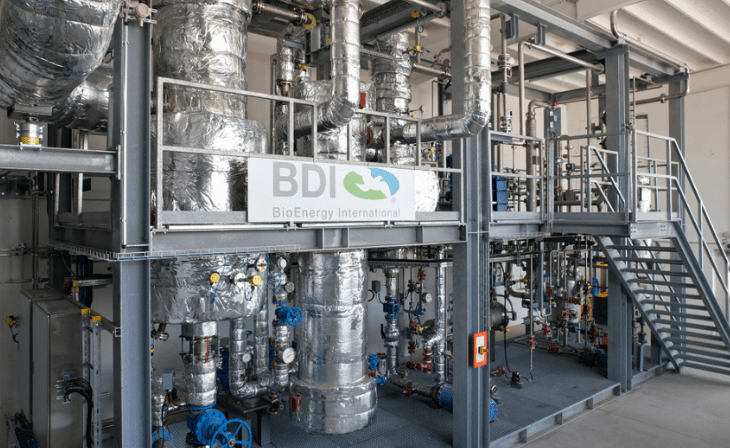

With the order to build an innovative SynCycle plant, the Styrian-based plant manufacturer BDI-BioEnergy International GmbH (BDI) is playing a central role in the sustainable transformation of the plastics industry. As this is the first reference plant with SynCycle technology on an industrial scale, the project is a significant milestone for BDI.

With the innovative SynCycle technology, BDI offers an efficient solution for the chemical recycling of plastic waste. The plant isolates polyolefins from waste streams and converts them into pyrolysis oil. Thanks to this technology, plastic waste that would otherwise be disposed of in incineration plants or landfills can be processed into valuable intermediate products for the chemical industry.

The pre-treatment of the raw materials and other parts of the supply process are carried out by BDI’s partner companies, HydroDyn Recycling GmbH and Next Generation Recycling GmbH (NGR).

Efficient recycling of plastic waste: In the SynCycle plant, polyolefins (polyethylene, polypropylene) are isolated from waste streams originally intended for incineration or landfill and converted into valuable pyrolysis oil, which in turn can be used to produce new plastics. In this way, not only is the carbon contained in the waste saved from incineration, but dependence on fossil fuels is also reduced.

Conserving resources and reducing CO2 emissions: The reuse of pyrolysis oil in the plastics industry and its use instead of intermediate products made from crude oil contributes to a significant reduction in CO2 emissions. In this way, the incineration of non-recyclable plastic waste can be avoided and the demand for crude oil can be reduced at the same time.

Milestone project – The first industrial reference plant: This project marks the first phase of the expansion of the GREENERTIS site in Tarragona into a center for decentralized chemical recycling and paves the way towards a more sustainable and environmentally friendly future.

By working closely with GREENERTIS, BDI is setting new standards in recycling. Together they are making an important contribution to reducing pollution and promoting the development of sustainable technologies. The Tarragona plant will serve as a model for future chemical recycling projects and underlines the importance of innovation and collaboration in this industry.

“With this project, BDI is demonstrating its leading role in the development of environmentally friendly technologies and strengthening its position as a pioneer in the bioenergy and recycling industry. The SynCycle plant is not only a technical breakthrough, but also an important step towards a more sustainable and recycling-oriented economy,” said Manfred Baumgartner and David Niederl, Managing Directors of BDI.

“With the development of the plant in Tarragona, GREENERTIS, whose main investor is the Portuguese industrial group SONAE Capital Industrials, is making a clear commitment to the circular economy and sustainability. From the third quarter of 2025, this plant will produce 36,000 tons of Circular-Oil® annually by reusing 50,000 tons of complex plastic waste. This is the first step of GREENERTIS’ ambitious project to establish several sites in Europe in the coming years,” said GREENERTIS CEO Josep Maria Calderó.

[Source: https://bdi-bioenergy.com/]