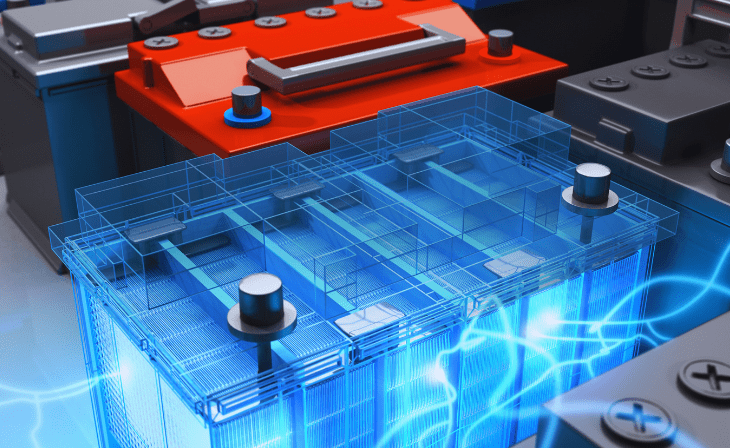

The switch to electromobility plays an important role in achieving climate neutrality. According to estimates by the European Commission, at least 30 million electric vehicles are expected to be on the EU’s roads by 2030. However, their batteries have a limited lifespan and will have to be disposed of over time. However, the old lithium-ion batteries from electric cars also contain valuable materials such as lithium, cobalt, nickel and copper. Although they can be recycled, this has so far been easier and quicker said than done.

A dozen European research partners

In order to achieve the necessary sustainability for lithium-ion batteries, the recycling of the batteries must be improved. Of lithium, for example, which is enjoying ever-increasing demand at rising prices. The Horizon Europe project “BeyondBattRec” aims to integrate new technological tools to advance recycling processes.

The aim of the project, which runs until the end of 2028 and involves around a dozen European partners, is to make recycling more efficient, environmentally friendly and cleaner. “The aim is to drastically reduce waste and emissions and strengthen European resource independence,” an acib spokesperson told APA.

Sulphuric acid bacteria take on the task

According to acib, the focus is on new processes for sorting, deactivating, dismantling and recovering battery materials. Among other things, the acib team is working on the recycling of cathode materials using innovative bioleaching processes. Bacteria could play a key role in this: “Sulphuric acid bacteria can provide an environment to extract the lithium from the battery,” said the acib spokesperson, summarizing the development approach. Mixed cultures of sulphur-oxidizing bacteria from sulphur waste left over from biogas desulphurization could be used for the bioleaching process.

acib has a long history of successful bioleaching projects, i.e. the use of microorganisms to extract valuable metals from ores or waste. In the case of copper, around 20 percent of global production is already obtained through bioleaching, while there is still a lot of untapped potential for lithium, according to acib.

[Source: APA Science, 3.3.2025]

Battery recycling of tomorrow

7.45 million euros in EU funding for efficient pre-treatment of lithium-ion batteries

Lithium-ion batteries are essential for electromobility, renewable energy and many electronic devices. As Europe strives to transition to a greener economy, batteries are expected to play a crucial role in the strategy to achieve climate neutrality by 2050. However, the environmental and economic challenges in this context need to be addressed urgently to ensure sustainability. The BeyondBattRec project, which is funded with €7.45 million under the Horizon Europe program, is at the forefront of these efforts.

Despite the importance of lithium-ion batteries in achieving the EU’s climate targets, the inefficiency of current recycling processes limits the recovery of valuable materials, increases the environmental impact and increases dependence on imports. This is where the BeyondBattRec consortium comes in: Led by Aalborg University in Denmark, 12 leading partners from seven countries, including VARTA Microbattery GmbH, Siemens, Accurec Recycling GmbH, Andaltec, UVR-FIA GmbH, Shift Materials, University of Jaén, EurA AG, Coventry University, ACIB GmbH (from Austria) and Tes AMM, are working on innovative recycling technologies.

The aim is to efficiently recover up to 95% of critical metals such as cobalt, nickel and copper and 70% of lithium. The aim is to drastically reduce waste and emissions and strengthen European resource independence. The project focuses on new processes for sorting, deactivating, dismantling and recovering battery materials. The scalability for industrial application is also being examined. Through comprehensive technology impact assessments, the project will address material recycling rates, zero-waste targets, emission reductions and socio-economic benefits that could be realized in the EU27 countries and associated states.

BeyondBattRec’s vision goes beyond technological advances. The project aims to establish Europe as a frontrunner in innovative battery recycling technologies and to build a circular value chain that promotes both industrial growth and societal benefits. By strengthening the EU’s industrial resilience and resource independence, the project directly supports the objectives of the European Green Deal and facilitates the sustainable transformation of the energy and transport sectors.

Further information:www.beyondbattrec.eu

[Source: OTS acib, 3.3.2025]