BINDER+CO AG

World market leading company for glass recycling and difficult to screen secondary raw materials

Binder+Co: Machinery & plants for industry

Binder+Co is an internationally successful specialist in machinery and complete systems for comminuting, screening, drying, sorting, wet-processing as well as packaging and palletising of bulk materials of all kinds. The company, which is based in Gleisdorf, Styria, concentrates on the three segments of processing technology, environmental technology and packaging technology, and is a global market leader in the fields of screening technology and glass recycling.

The machinery of Binder+Co in the overview

Comminuting technology: Efficient crushing of industry minerals, construction materials and construction waste.

Screening technology: World market leader in materials hard-to-screen, conventional and special screening machines.

Wet-processing: Sand trap SANDEXX, bucket wheel, log washer, dewatering screens.

Drying technology: Efficient drying and cooling with fluid-bed technology.

Thermal expending: BUBLON for the production of lightweight construction material and lightweight fillers.

Sorting technology: Sorting technology on highest level. World market leader in glass sorting.

Packaging technology: Packaging technology on highest level by STATEC-BINDER.

BINDER+CO AG

Grazer Straße 19-25

8200 Gleisdorf, Österreich

8200 Gleisdorf, Österreich

Your Contact

Almuth Schnehen

Kommunikation & Marketing

Kommunikation & Marketing

BIVITEC - screening of difficult materials

With BIVITEC, Binder+Co starts where conventional screens fail. BIVITEC stands for highly efficient screening of difficult materials, typical in the processing of secondary raw materials.

Screening is an important step in the processing of bulk materials. Next to conventional screens, such as circular vibrating screens and linear vibrating screens, Binder+Co also supplies screens for especially difficult requirements.

Advantages of the BIVITEC Flip Flow Screen

- Wear to the sides of the screen is prevented by the ox-horn system (laterally raised screen panels).

- Screw less fastening system of screen panels allows them to be replaced fast.

- Optimum adjustment to the task in hand by simply changing the vibration parameters.

- Optimum side sealing by means of the ox-horn system avoids loss of material.

- Optional monitoring of bearing and amplitudes for coordination and planning of maintenance intervals

Contact to your Solution

Heinz Raith

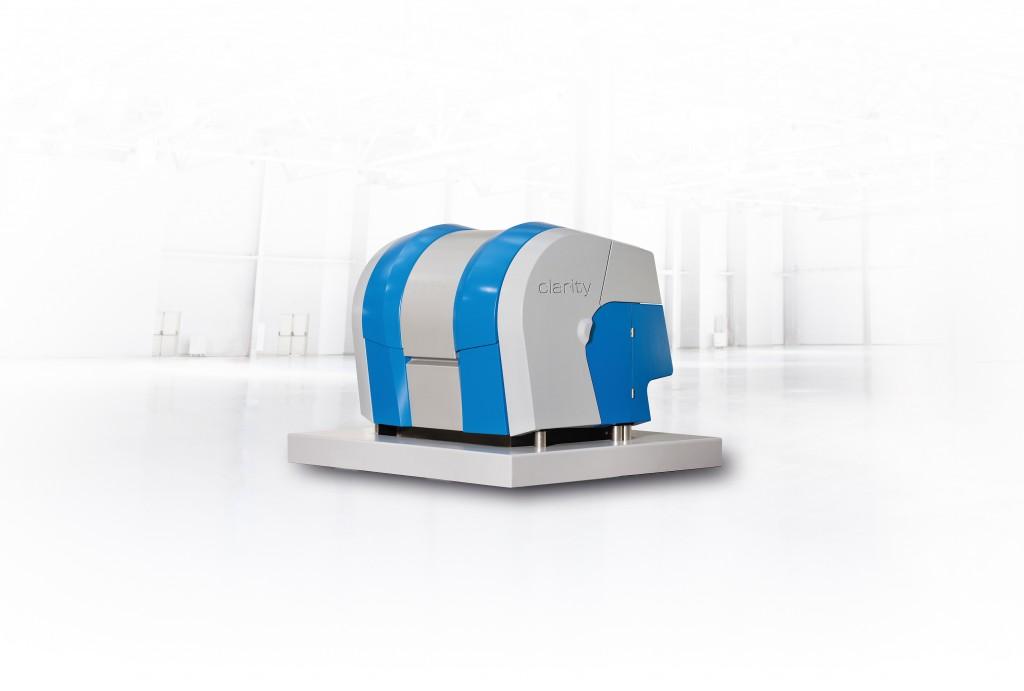

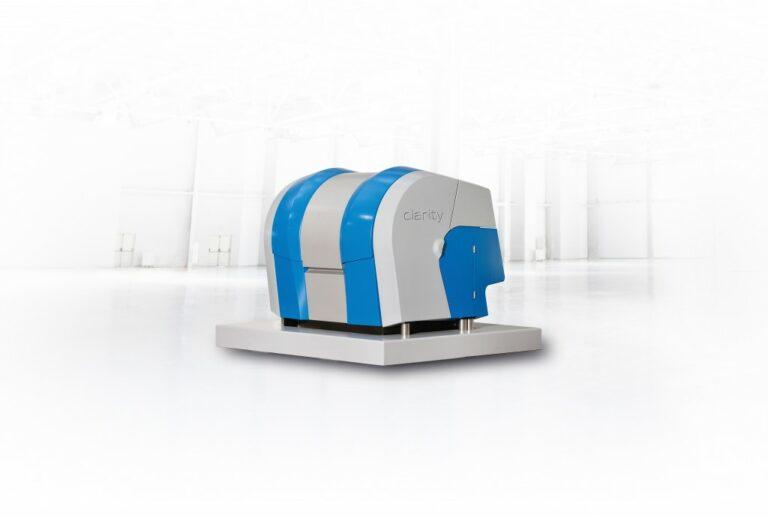

CLARITY - sensor-based sorting system

Binder+Co’s revolutionary sensor-based system sorts glass, plastics, packaging waste, WEEE, paper, demolition waste and much more according to colours and type of materials.

Products:

- CLARITY glass

- CLARITY plastic

- CLARITY msw (für Haushalts- und Gewerbemüll zur Störstoffabscheidung und Materialtrennung)

- CLARITY paper

- CLARITY rdf (for the extraction of substitute fuels)

- CLARITY electro

- CLARITY metal

- CLARITY slag (Recovery of glass and metal from incineration slags)

- CLARITY demolition

Contact to your Solution

Christian Leitner

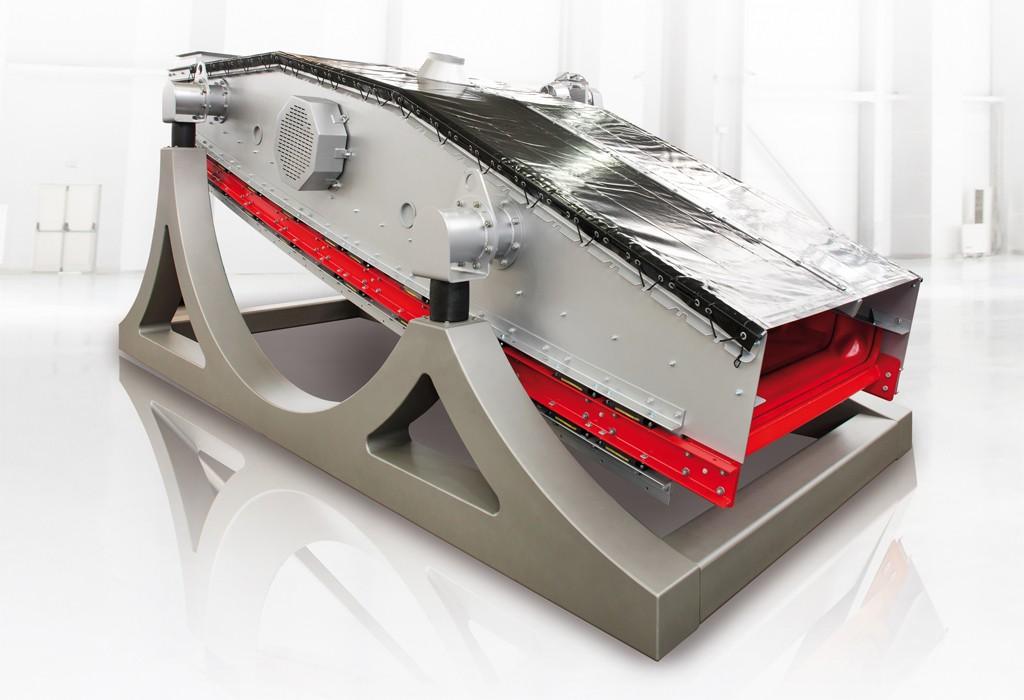

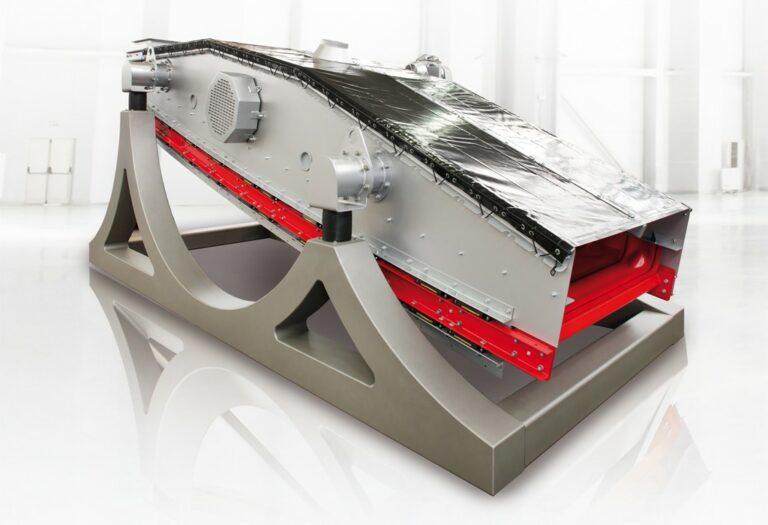

BIVITEC e+ - flip flow screen

As the latest flip flow screen from Binder+Co, it has a frequency transformer in the motor that lets you set the ideal vibration characteristics for the specific task.

BIVITEC e+ - Efficient screening made easy

Do you need to screen difficult material that is subject to seasonal, weather, or other changes? Then the BIVITEC e+ is the right choice. As the latest flip flow screen from Binder+Co, it has a frequency transformer in the motor that lets you set the ideal vibration characteristics for the specific task.

When screening with the BIVITEC e+ the near-total mass balancing means there are only minimal dynamic loads. In fact, they are so low that support springs aren’t needed. Thanks to the low dynamic loading, the substructure can be made much more economically, or if there already is one in place, it doesn’t need to be reinforced.

With the BIVITEC e+ flip flow screen, your operating costs are low

Thanks to its light construction the BIVITEC e+ uses only very little energy. This protects the environment and keeps costs down. Further investment is low, since a retrofitted BIVITEC e+ can use existing infrastructure. At the same time you benefit from all the advantages of the BIVITEC flip flow screen! See the infobox on these advantages of the BIVITEC e+.

BIVITEC e+ The best of two classics

The BIVITEC e+ combines two ingenious technologies from Binder+Co in one screen – low dynamic loading through the mass balancing of a resonance screening machine, plus the BIVITEC flip flow system. This gives a light machine that needs less power. In fact, with the BIVITEC e+ you can save up to 40 % of the weight and up to 65 % of the energy use of a conventional machine. Thanks to the low dynamic loads, the substructure the BIVITEC e+ is mounted on can be as narrow and economical as the machine itself. The BIVITEC e+ is designed compactly, so that no motor components or other parts protrude. As many decks can be stacked as needed, and a low-dust design is available.

Advantages of the BIVITEC e+ flip flow screen

• Low dynamic loads allow a compact and low-cost base.

• Low energy consumption keeps operating costs low.

• Perfect adaptation to individual tasks through preset operating modes.

• Wear on the sides of the screen is prevented by the proven ox-horn design of the screen mats.

• The screwless screen panel mounting system makes replacements fast.

• Optional monitoring of bearing and amplitudes for coordination and planning of maintenance intervals.

Tasks & applications

• Screening of bulk materials, including hard to screen materials

• Dry screening

• Moist screening

• Wet screening

• Mobile version

Contact to your Solution

Helfried Gschaider

Produktmanager

Produktmanager