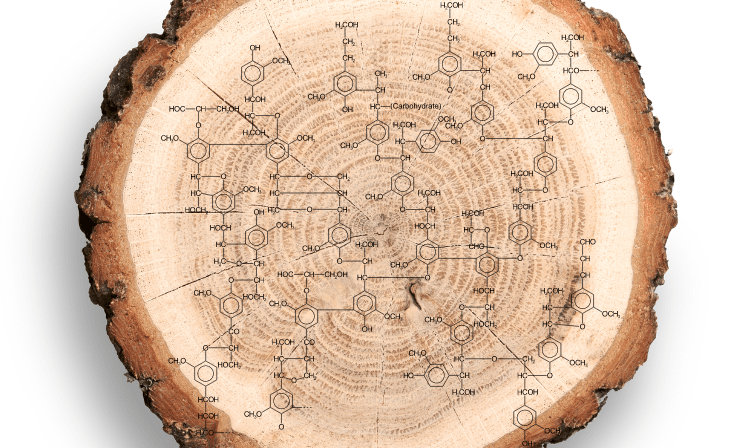

Lignin is a substance in wood that binds wood fibres together. In pulp production, lignin is separated from the fibres into black liquor in the chemical cycle and used as bioenergy. Lignin could also be used in chemical and material applications.

Metsä Group and ANDRITZ will focus on developing the production process of the new lignin product and its integration with the bioproduct mill, as well as the product properties suitable for various end uses. The demo plant project also involves Dow, a leading material science company, which will develop high-performance bio-dispersant plasticizers for concrete and gypsum applications, based on the lignin product produced at the plant.

“Our goal is to efficiently use the side streams of pulp production and ensure they produce the greatest possible added value. We want to develop new products made from renewable natural resources that can replace fossil-based raw materials and products,” says Ismo Nousiainen, CEO of Metsä Fibre, part of Metsä Group.

ANDRITZ has been developing lignin recovery and modification technology concepts as part of its initiative to enable pulp mills to convert side streams into value-added products. Kari Tuominen, CEO & President of ANDRITZ Oy, states: “We are thrilled to be able to test this technology in continuous process conditions at the Äänekoski bioproduct mill. In addition to validating markets for the new lignin product, the demo scale gives us valuable insights for integrating the LigniOx process into a bioproduct mill and scaling it up for industrial use.”

“At Dow, we are committed to collaborating with stakeholders to innovate and bring more sustainable solutions to the market,” says Raquel Fortes, Global Business Director of Dow Construction Chemicals. “This new technology would further expand Dow’s bio-based product offerings to meet the future needs of the building and construction industry.”

In a pilot-scale EU project coordinated by VTT Technical Research Centre of Finland, Metsä Group, ANDRITZ and Dow have already demonstrated the suitability of modified lignin as a replacement for fossil-based chemicals in concrete production.The Äänekoski mill area is Metsä Group’s largest, housing a paperboard, veneer and bioproduct mill. Äänekoski is also home to Metsä Group’s demo plants for the Kuura textile fibre and Muoto fibre product.