In Austria alone, around 220,000 tons of textile waste are produced every year, of which almost 80 percent is incinerated. This means that valuable raw materials are irretrievably lost. A team led by Thomas Harter from the Institute of Biobased Products and Paper Technology has a sustainable solution to this problem: the researchers have developed a process to recover the fibers from cotton-based used textiles and use them to produce paper for packaging materials. Compared to conventional recycled paper, the paper with textile fiber content proves to be significantly stronger.

“Strictly speaking, the conversion of textile fibers into paper is a downgrade,” says Thomas Harter. “However, from an environmental point of view, it has a major advantage: the paper fiber cycle is highly closed, with recycling rates of 83% in the packaging sector. If we bring the valuable textile fibers into this cycle, they remain usable for a long time.” Recycled textiles can be an important source of raw materials for the production of packaging paper and help to reduce the amount of waste paper imports currently used for this purpose.

Very similar to normal paper suspension

To make paper from old items of clothing, they are first cut into small shreds and soaked in an aqueous solution. This mixture of water and shreds is ground in order to separate the interwoven cotton fibers without knotting or forming lumps. As part of his master’s thesis, Alexander Wagner determined the most suitable grinder, the necessary grinding time and the optimum ratio of water to textiles in order to extract the maximum amount of usable fibers from the textile scraps. “At the end of our tests, we obtained a suspension that is very similar to a normal paper suspension and that we can process into paper using established methods,” says Thomas Harter.

Significantly stronger than conventional recycled paper

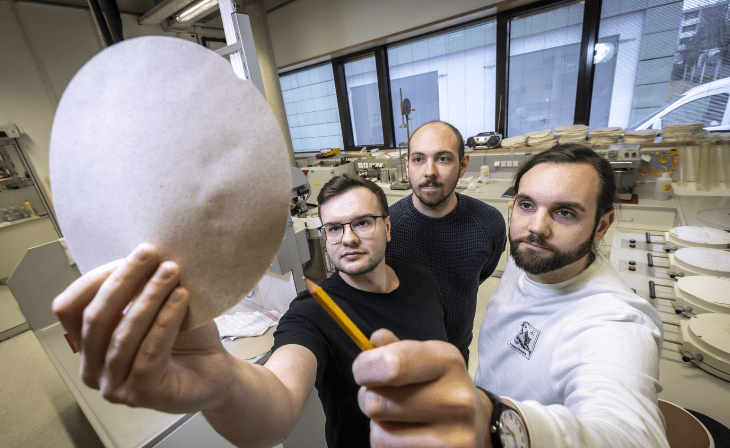

Visually, the paper with textile content hardly differs from ordinary recycled paper, it is slightly brownish with occasional colorful speckles that come from colored clothing. However, these spots of color are irrelevant for cardboard boxes and other packaging materials. Tensile tests have shown that the addition of textiles increases the strength of recycled-based paper: “Even with a textile-based proportion of 30 percent, the paper is significantly stronger, while the processability remains the same,” says Alexander Weissensteiner, who is also working on optimizing the recycling process as a Master’s student. This is due to the length of the fibers: “With recycled waste paper, the fiber lengths are quite short. Our recycled textile fibers are significantly longer at 1.7 millimeters.”

The researchers’ next goal is to reduce the energy consumption of the milling process. To this end, they are testing additives such as light acids and alkalis as well as enzymatic pre-treatments to support fiber disintegration in the grinding unit. “We also want to take the next scaling step and implement the process on industrial devices,” says Thomas Harter.

Further information:

Thomas HARTER

Dipl.-Ing. Dr.techn. BSc

TU Graz | Institute for Biobased Products and Paper Technology

Phone: +43 316 873 30764

harter@tugraz.at

[Source: PA TU Graz, 27.2.2025]