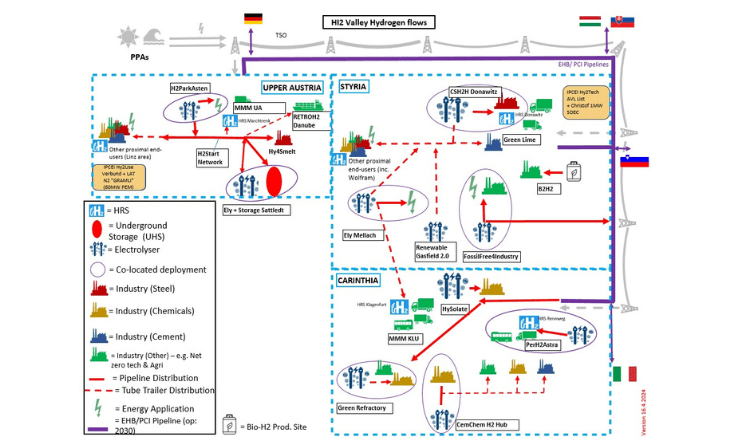

The projects within the Hydrogen Valley cover the entire value chain – from the production and transportation to the storage and use of green hydrogen. New plants are planned to produce more than 10,000 tons of hydrogen per year in the three federal states. The Hydrogen Valley will thus make a significant contribution to the decarbonization of domestic industry.

The entire Hydrogen Valley, which is being implemented under the leadership of the WIVA P&G research institute, involves 48 national and international partners in the 17 projects. These focus on applications in industry (56 percent), energy (23 percent) and mobility (21 percent). Of the 17 projects, six each are being implemented in Styria and Upper Austria and five in Carinthia.

The timetable envisages concrete planning from the beginning of 2025 to the end of 2026, followed by the construction of the plants, which will run until the end of 2028. The plants will be further optimized by 2030. In the coming weeks, concrete negotiations for funding will be held with the EU.

130 million for Styria – hydrogen turbo for Styrian industry

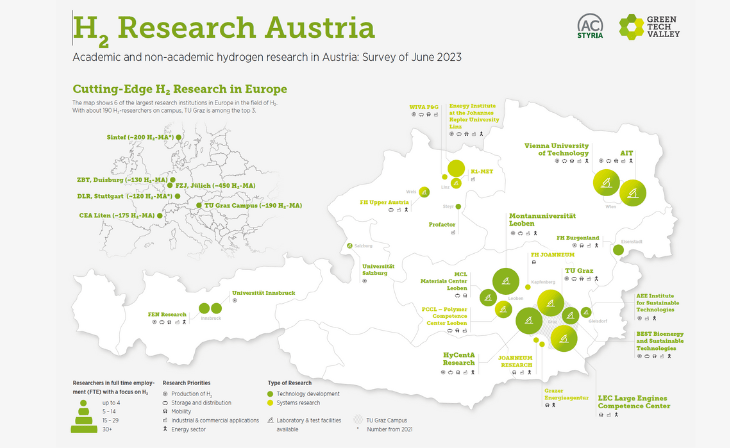

The six projects planned in Styria will trigger investments of around 130 million euros. This will further strengthen Styria’s hydrogen expertise. Already, 60 percent of the hydrogen researchers in Austria are concentrated in our province. In addition to the lively research activities, the award of the Hydrogen Valley will also increase economic activities in the field of hydrogen, which will accelerate the transformation. International competitiveness and transnational network connections will also be strengthened. Further projects will therefore be initiated in the coming years.

Hydrogen research at Graz University of Technology and Montanuniversität Leoben has already been strengthened with 17 million euros. With its expertise, Styria is ideally positioned to drive the Hydrogen Valley forward together with Upper Austria and Carinthia.

Styrian successes in the field of hydrogen

One example of this is the particularly strong research activities in this area: 20 Austrian university and non-university institutions are active in research into green hydrogen technologies. With the K1 centers HyCentA, LEC Large Engines Competence Center and BEST Bioenergy and Sustainable Technologies as well as other TU Graz institutes, the TU Graz Campus is among the top three in the EU.

Styrian companies are increasingly taking advantage of the market opportunities arising here and are in some cases world leaders in the field of green hydrogen technologies and applications. Andritz AG, for example, is building a 100 MW electrolysis plant for the Salzgitter Group. From 2026, the plant will supply green hydrogen for the production of green steel. As the largest engineering company in the field of hydrogen, AVL has around 650 employees worldwide in the field of hydrogen and is significantly involved in European IPCEI projects and initiatives.

Numerous green tech start-ups are also relying on this “champagne of the energy transition”, such as H2i GreenHydrogen, which builds high-performance electrolysis modules, i.e. the heart of hydrogen plants, in Graz. Redeem Solar Technologies and Rouge H2 Engineering are also at the forefront here.

Energie Steiermark is focusing on green hydrogen in numerous research and company projects. The pilot plant in Gabersdorf (southern Styria) is the first public production facility for green hydrogen in Austria. Energie Steiermark is a key and strong partner in the new Hydrogen Valley.

Styrian focus on energy-intensive industry

According to the EU, the energy-intensive industries of steel, cement and raw materials, which are strongly represented in Styria, are the most difficult to decarbonize. This makes the use of green hydrogen all the more essential here. This is also because some of the conventionally produced hydrogen already used in this sector is to be converted to 50 percent green production in the EU by 2030. There is therefore a great need for action here, and these sectors are all being decarbonized on a pilot basis in Styria’s Hydrogen Valley.

A total capacity of 36.25 MW of new electrolysers will be installed in Styria – which corresponds to the capacity of two Mur power plants (each with around 18 MW). These plants use renewable electricity from photovoltaics, wind, hydropower and grid surpluses to produce green hydrogen by separating oxygen from water. From 2028, around 5,500 tons of green hydrogen will be produced in Styria every year. So far, only around one MW of green hydrogen production has been installed in Styria. The Hydrogen Valley projects will multiply the installed capacity to over 37 MW.

Smart solutions for cheaper hydrogen

In addition to the production of hydrogen from 2028, the focus is also on increasing system efficiency. The aim is to make the best possible use of waste heat and increase cost-effectiveness throughout the entire life cycle. The project to establish the first freely accessible tube trailer network and to standardize hydrogen systems and infrastructure (in particular through EU-wide standardized connections for hydrogen transports) is outstanding throughout Europe. This will reduce costs and further remove existing hurdles.

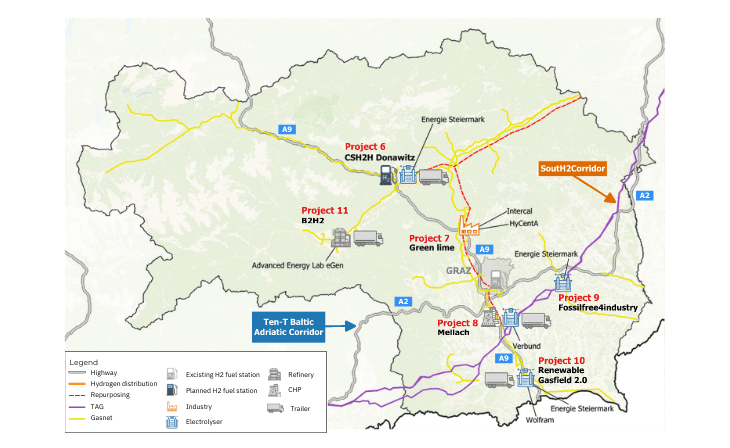

Furthermore, the planned hydrogen pipeline “SoutH2Corridor” from North Africa via Italy, Carinthia, through Styria and on to Germany will be taken into account in the further hydrogen expansion on site.

Strong Styrian partners

More than a dozen strong partners come from Styria, above all RHI Magnesita, InterCal Austria, Energie Steiermark & Energie Netze Steiermark AG, AVL, Verbund AG, HyCentA, BEST, ABL (Advanced Bioenergy Lab). Styrian pioneers and potential customers and users include voestalpine AG, Primetals Technologies Austria and Wolfram Bergbau und Hütten AG.

Regional coordination in Styria and Carinthia is carried out by the Green Tech Valley Cluster in cooperation with ACstyria. The central technical partner for all three federal states is HyCentA – this K1 center at Graz University of Technology develops the majority of the projects with its technical expertise through to implementation.

The six Styrian projects

– Leoben hydrogen hub (CSH2H Donawitz)

On-site production in Donawitz with project partner Energie Steiermark of around 3,000 tons of hydrogen per year, part of which is used directly in steel production by voestalpine.

– 100 percent renewables for industry in Weiz (FossilFree4Industry)

One sub-project in the real-world laboratory for 100 percent renewable energy supply in a region is the planning of an 8 MW electrolyzer for hydrogen production for industrial use. The feasibility of various project variants (hydrogen feed-in to the gas grid, SNG production, etc.) is being evaluated.

– South Styrian pioneering project is being scaled up (Renewable Gasfield 2.0)

The existing Renewable Gasfield was planned modularly with foresight and will be further expanded in the HI2 Valley. H2 delivery via trailer, gas grid and methanation plant.

– Sustainable quicklime (Green Lime)

Quicklime is a versatile and essential raw, building and construction material. HyCentA and InterCal Austria are breaking new ground for CO2-reduced production using hydrogen.

– Surplus electricity to hydrogen (Mellach)

Construction of a six MW electrolysis plant by Verbund based on renewable energies and surplus electricity to produce approx. 760 tons of hydrogen per year. It will be used in the mobility and industrial gas sectors.

– Biomass to hydrogen in Zeltweg (B2H2)

The planned plant of Advanced Bioenergy Lab – Austria (ABL) produces a hydrogen-rich raw wood gas from biomass. The hydrogen yield is maximized in just a few conversion steps and the remaining gases are used internally. The high-purity hydrogen obtained is supplied to industrial partners. A connection to the hydrogen grid is also planned after 2030.