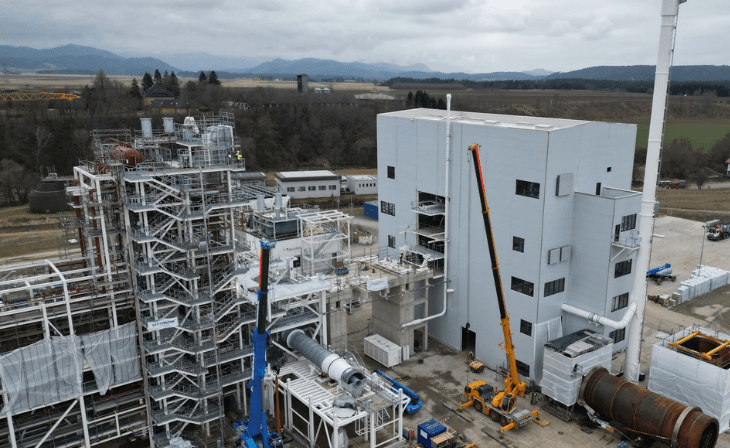

Treibacher Industrie AG, a leading company in the metallurgical and chemical industry headquartered in Althofen, Carinthia, is consolidating its commitment to sustainability and environmental protection with a significant investment of almost 120 million euros in a new recycling plant that focuses on the circular economy. This plant will cover up to 15% of Treibach’s electricity requirements by converting waste process heat into electricity, and the topping-out ceremony for the recycling plant, which will be celebrated on March 7, 2024 at the site of Recycling Plant 2, marks a milestone in this forward-looking project.

The RC2 plant will specialize in the recycling of spent metal-containing catalysts from the oil industry. Spent catalysts from refineries contain valuable metals such as molybdenum, vanadium and nickel. The waste product is safely treated in Treibach and processed into valuable materials, with a recycling rate of an impressive 99 percent. Treibacher Industrie AG, already market leader in the recycling of catalysts from the oil industry and known for the highest environmental and quality standards, pursues the goal of closing material cycles and contributing to the Green Deal, sustainability and the circular economy. Every year, recycling can save more than 500,000 tons of ore mining. The recovered raw materials play an important role on the European Union’s (EU) list of supply-critical raw materials.

The commissioning of the new recycling plant is planned for summer 2024 and should be completed by the beginning of 2025. Rene Haberl, CEO of Treibacher Industrie AG, emphasized the importance of these steps: “The construction of this recycling plant is a clear sign of our commitment to sustainable practices in our business operations and for the Althofen site.”