How can technological innovations be combined with the circular economy and sustainability? This is a challenge that researchers at the Institute of Environmental Systems Science at the University of Graz are tackling. As a partner in a new EU project, Rupert Baumgartner’s team is contributing its expertise in sustainability assessment for industrial production processes. The “HaloFreeEtch” research project focuses on the development of new, environmentally friendly production methods for semiconductors using halogen-free etching processes.

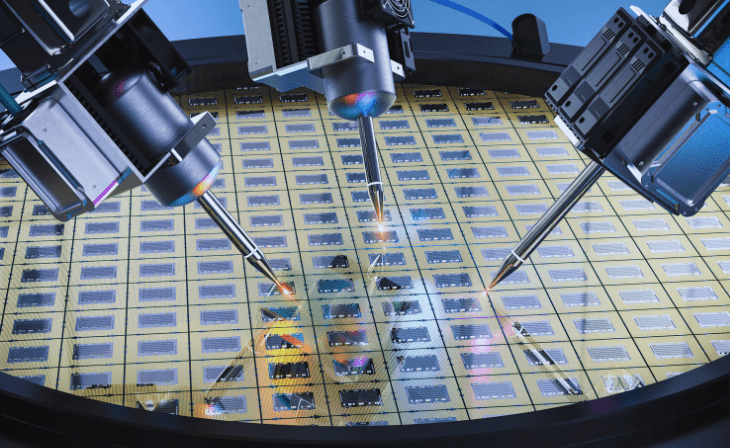

Semiconductors are materials whose electrical conductivity is controlled by applying a voltage. This makes them essential components in all electronic devices. Plasma etching is used in their industrial production, primarily from silicon. In this process, material is removed through a chemical reaction with halogens such as sulphur hexfluoride (SF6), tetrafluoromethane (CF4), trifluoromethane (CHF3) or octafluorocyclobutane (C4F8). The process poses considerable environmental and health risks. The aim of the “HaloFreeEtch” research project is to replace halogens in etching processes for silicon and silicon oxide with more sustainable alternatives.